EUDR Implementation Guide: Compliance Path for Wooden Tableware Enterprises

The implementation timeline of the EU Deforestation Regulation (EUDR) has been adjusted to provide enterprises with more preparation time. According to the latest revision, large enterprises must fully comply with the regulation by December 30, 2025, while the compliance deadline for micro and small enterprises has been extended to June 30, 2026 . This extension offers valuable buffer time for wooden tableware manufacturers to establish robust supply chain traceability systems and compliance procedures, ensuring smooth access to EU markets.

Scope of Regulation: Clear Regulatory Requirements for Wooden Tableware

EUDR covers seven categories of commodities including wood and wood products, with disposable wooden tableware explicitly within the regulated scope, which is the core prerequisite for enterprises' compliance work. The core requirement mandates enterprises to prove that product production did not cause deforestation after December 31, 2020, and must establish full traceability systems from raw material origin to EU markets—information of every link, from forest harvesting to finished product delivery, must be verifiable and traceable .

Specifically, wooden tableware enterprises need to focus on collecting two types of key data:

1. First, the geographical coordinates of raw material sources to accurately locate wood harvesting areas.

2. Second, land use history records, including at least changes in land use since December 31, 2020, to prove that raw material origins are not involved in deforestation.

These data must be audited by third-party certification institutions recognized by the EU, and only after passing the audit can the basic compliance conditions be met .

Core Compliance Requirements and Implementation Steps

For wooden tableware enterprises, EUDR compliance requires establishing a "three-level risk assessment system" to ensure no deforestation risks in all links of the supply chain:

1. The first level is basic qualification review, collecting suppliers' forest management licenses, environmental protection filing documents and other qualification materials, as well as ecological environment assessment reports of production sites.

2. The second level is geographical risk verification, using the "forest monitoring map tool" officially provided by the EU to compare the overlap between raw material origin coordinates and high-risk deforestation areas;

3. The third level is dynamic risk control, adopting risk mitigation measures such as regular on-site audits and replacement of alternative suppliers for suppliers with potential risks .

In addition to risk assessment, enterprises also need to fulfill regular declaration obligations: they must submit a compliance statement every year, covering the types and specific quantities of wooden tableware products exported to the EU that year, the complete list of suppliers, and the geographical coordinates of raw material origins; the compliance statement must be publicly disclosed on the EU "Deforestation-Free Commodities Supervision Platform" to accept supervision and verification by regulatory authorities and the public .

The specific implementation steps can be promoted in five phases:

1. Screen and identify third-party audit institutions with EU-recognized qualifications, and sign cooperation agreements

2. Comprehensively sort out existing suppliers, and collect geographical coordinate certificates of raw material sources and land use history documents

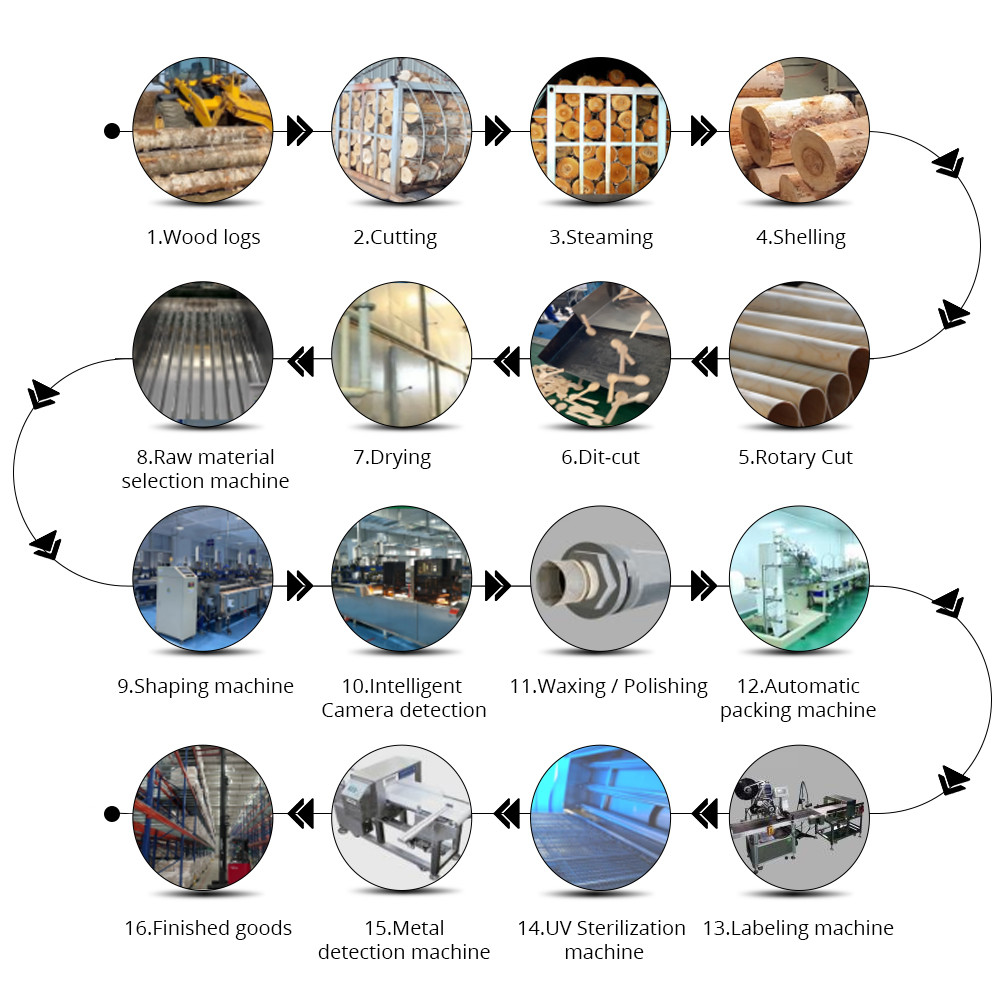

3. Build a digital supply chain recording system to realize traceability and query of every process from forest to finished products

4. Formulate internal risk assessment rules, clarifying risk level classification standards and corresponding mitigation measures

5. Prepare compliance statements in accordance with EU format requirements, and complete platform filling and public disclosure

Transitional Period Action Recommendations and Compliance Risk Tips

Although the compliance deadline has been extended, wooden tableware enterprises still need to start compliance preparation work as soon as possible—the establishment of a compliance system, collection and verification of data, and commissioning and operation of the system all require a certain cycle. Taking early action can avoid compliance omissions due to time constraints in the later stage. From a practical perspective, it is recommended that large enterprises complete supplier evaluation and traceability system construction by the end of 2024 to ensure sufficient time for trial operation adjustments; micro and small enterprises can implement in phases, but need to complete the basic framework construction within 2025 to reserve space for subsequent detailed improvement.

It should be particularly noted that EUDR imposes heavy penalties for violations: wooden tableware products that do not meet compliance requirements will be seized by EU customs; enterprises may be fined up to 4% of global turnover; those with serious circumstances will also be banned from entering the EU market, and there is no clear upper limit for the ban period. These consequences will directly affect the international business layout of enterprises, so compliance work must be promoted as a key task at present .

In addition, enterprises can use compliance work to enhance product competitiveness: on the basis of completing EUDR compliance, they can further apply for international green certifications such as FSC Forest Certification and PEFC Sustainable Forestry Certification to strengthen the environmental attributes of products; in the promotion to EU customers, proactively display the supply chain traceability system and compliance certificates, highlight the "deforestation-free" advantage, align with the EU consumers' demand trend for sustainable products, and add impetus to business expansion.

The implementation of the EU Deforestation Regulation is essentially an important signal for the transformation of global trade towards "sustainable development". For wooden tableware enterprises, compliance is not only a "stepping stone" to enter the EU market, but also an inevitable choice for enterprises to achieve long-term healthy development. By building a sound compliance system in advance and strengthening green production capabilities, enterprises can not only avoid trade risks, but also establish a responsible brand image in the international market, laying a solid foundation for continuously expanding global business.